Artproof Diasec®

ProDig erbjuder silikonmonteringar av högsta kvalitet och är svensk representant för Artproof i Tallinn, Estland.

Artproof är den enda aktören med Diasec®-licens i Skandinavien.

Diasec® kan beställas med följande ytor:

• Plexi= 3 el 4mm, TrueLife reflexfritt 3mm, HC reptåligt 4mm och matt 3mm

• Glas Optiwhite= 4 mm (Obs ca 22 kg/kvm)

• Plexi går också utmärkt att få som fria former med CNC-fräsning i alla storlekar (se bild av Helena Blomqvist)

• Baksida av 1,5mm aluminium eller Dibond 3mm.

Bakram för upphängning av aluminium.

• Max storlekar ett stycke: 150 x 300 cm för glas, 200 x 500 cm för plexi.

• Och alltid med syrafria pigmentprints för maximal permanens!

Till höger: Diasec®CNC-fräst figur av Helena Blomqvist och

Diasec® 100x285 cm, Maria Friberg

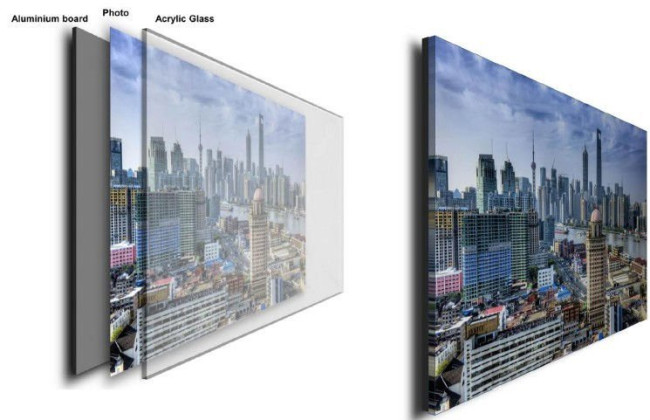

Diasec® is a patented mounting process which permanently joins

together transparent glass and prints. It is the only mounting method

that leaves the final work totally free of streaks or bubbles. And

because the print is glued to glass the result is a completely flat

mounted image.

The process was invented by Heinz Sovilla-Brulhart in 1969. It is a

registered trademark and Artproof is the only authorised licence

holder in Scandinavia, and we hold the exclusive rights to the process

in Finland and the Baltic countries.

Because the Diasec® process makes the artwork more resistant to UV

light and fading, as well as to mechanical wear and tear, Diasec® was

initially used for the design of prominent administrative buildings.

However, from the mid-eighties and on, more and more photographic

artists started to make use of the process for the presentation and

preservation of their work.

Thanks to the Diasec® process, especially when face-mounting to

glass is combined with back mounting on an aluminium panel, the

print is airtight and effectively protected against mechanical stress

and harmful environmental influences.Diasec uses a primer and

liquid gel, not sheet film adhesive. The biggest advantage of this is

claimed to be that air bubbles and creases in the final product are

minimized.

The Diasec gel is neutral curing and has an inbuilt ultra violet

filter. It contains no plasticizers and is resistant to fungicidal,

bacterial agents, and airborne pollutants. After curing, the whole

airtight panel remains chemically inert and stable. The finished

product remains flexible, enabling it to withstand changes in

temperature and humidity, which affect works on paper. However,

the process is irreversible and if the glass is damaged there is no

way to salvage the print.

Diasec samples that were made in the 1970s show negligible colour

shift, the whites are still pure and there is no evidence of acid

erosion visible